Home

About

Greetings and welcome to my digital domain! I am Tauseef Ur REHMAN, a seasoned Chemical Engineer dedicated to the art of problem-solving. Whether I`m working on my job or pursuing my interests, I`m dedicated to making the world a better place. When I`m not busy with work, I enjoy exploring the mysteries of the universe and how it all began. Come along with me on this journey of learning and discovery as we add to our understanding of the world.

Follow me @

engOneer

Science Of Signs

LinkedIn

| Favourite Book: | Quran |

| Favourite Topics: | - Falsafa-e-Hayyat [Philosophy of Life] |

| - Advanced Physics [Quantum Mechanics; Relativity; Particle Physics] | |

| - Application of Physics [via Engineering] | |

| - Science Of Signs | |

| Hobbies: | - Woodworking |

| - Web Design & Development | |

| - Playing With Codes | |

| - DIY Electronics /Basic Robotics |

WHAT THEY SAY ABOUT ME? MY COLLEAGES, MY FRIENDS.

Arjmand Qayyum Amjad CEM® (CEnv)

Sustainability and Cleaner ProductionSustainability and Cleaner Production

We both studied at UET Lahore during 2001 - 2005, as class fellows

April 1, 2012 on LinkedIn

" He is one of the few engineers having design capabilities in his instinct. "

Zeeshan Qureshi

Process and Personnel Safety Management l Regulatory Compliance | Project Management | Process Optimization

We both worked at Engro Fertilizers Limited, Pakistan during 2006 - 2012, as peers on multiple projects.

May 31, 2016 on LinkedIn

" Tauseef is a special talent who never said ‘No’, whenever approached for his services on either technical based trouble shootings; or a social event requiring his multi media / presentation skills. He always came on top of those ordeals and displayed exceptional intellect and originality in his work. His consummate Engineering skills exudes professionalism and a wide range of understanding starting from core engineering concepts to using/utilizing soft-wares to his advantage. ‘Petro Street’ an Engineering web street to download and access free soft wares developed and supported by him and his friends is one of the commendable piece of work that he has recently exhibited. I wish him all the best for his future endeavors and recommend him for his all-round capabilities as a Process Engineer."

Faisal Hameed

Operations Manager

We both worked at Engro Fertilizers Limited, Pakistan during 2007 - 2008, as peers on multiple projects.

June 1, 2016 on LinkedIn

" I had an opportunity to work with Tauseef in Engro Fertilizers Ltd as a peer. He was amongst the most competent Process design engineers having excellent simulations skills and strong conceptual approach. Moreover Tauseef was good team player with easy going and supportive approach for rest of the group members. "

Usman Muhammad Sharif

Head of Non-Fuel Retail Business | Petromin Corporation KSA

Ex Coordinator - Dramatic Society - UET Lahore

We both studied at UET Lahore during 2001 - 2005, as class fellows

September 18, 2016 on Internal Group

"[Written in English scriptted Urdu language] Translate in English

One word: Keem-ya-gar, Baba gee

Hum mey koi genius hai to Tu hai. Kisi aur zamaney mey Tu Stefan Hawkings key saath Black hole theory per kaam ker raha hota ya phir Pakistan key liyey first rocket,satellite launch per kaam ker raha hota.

Mujhey aaj bhee mechanical waaley Ali Zaidi ka tujhey challenge Yaad hai. My. Pata nahi kahaan sey aya hai tu. Kis ney sikhaaya hai Tujhey yeh sab kuch.

Ooper sey khaaksaari ka yeh alam hai key na poocho. Balkey please poocho. Man chaley ka sauda mey mochi firdous Jamal shayed terey pey likha gaya thaa.

Dramatics mey agar kisi ney hamari productions mey jaan daali to wo Tu hi thaa. Jis tarha waseem akram ka team mey hona hi kafi thaa, waisey teri team mey presence hi kaafi thi. Tu thaa to raastey nikal ayey. My pehli dafa tu alhamra mey bethaa aur lights waaley ki po phar dee. Saalon sey theatre kerney waaley Peerzaadaas stage per kehney lagey, every one should learn from this guy.

Pata nahi tu kahan ghayeb hai. Ho sakta hai key tu Khudayi taakton sey mil ker kisi super secret mission per Dunya ko save kerta ho ya phir hum jaisey kisi bhatkey huyey ki Keemyagiri kerta ho. Shayed tu hamari bhee koi madad kerney bheja gaya thaa. "

Bilal Hameed

Interconnection & Process Expert | Sr. Manager Interconnect Management

TechniColor Team - Dramatic Society - UET Lahore

We both worked together at Dramatic Society, while studying at UET Lahore during 2001 - 2005.

October 9, 2005 on UET Dramatic Society MSN Group

" My Best Friend, My Partner, My Boss, My brother, My Doost, My Fav Person in Whole UETDS....... That person dont belong to Humans .... he is JIN .... simply Genious ....a persons with Kamal concept and idea about things he has ever studied or heard about.... a true Engineer .... i am proud to be a person who has worked mostly with him ... it was second Annual Function on which we were together on control Panels ...every time in whole year i am with him ... going to hall road .... going to Shah-Almi ... going to each and every corner of lahore .... in search of completing our ideas ..... the best kharrabi in that person is that he always completes his work on dead line .... not before that ...and i am very angry with him for that .... but the problem is that he always completes it in best of Way ..... Frankly speaking i am Jelous of that person ... so much perfection ..... so much idealism ... "

Arjmand Qayyum Amjad CEM® (CEnv)

Sustainability and Cleaner ProductionSustainability and Cleaner Production

We both studied at UET Lahore during 2001 - 2005, as class fellows

April 1, 2012 on LinkedIn

" He is one of the few engineers having design capabilities in his instinct. "

Zeeshan Qureshi

Process and Personnel Safety Management l Regulatory Compliance | Project Management | Process Optimization

We both worked at Engro Fertilizers Limited, Pakistan during 2006 - 2012, as peers on multiple projects.

May 31, 2016 on LinkedIn

" Tauseef is a special talent who never said ‘No’, whenever approached for his services on either technical based trouble shootings; or a social event requiring his multi media / presentation skills. He always came on top of those ordeals and displayed exceptional intellect and originality in his work. His consummate Engineering skills exudes professionalism and a wide range of understanding starting from core engineering concepts to using/utilizing soft-wares to his advantage. ‘Petro Street’ an Engineering web street to download and access free soft wares developed and supported by him and his friends is one of the commendable piece of work that he has recently exhibited. I wish him all the best for his future endeavors and recommend him for his all-round capabilities as a Process Engineer."

Faisal Hameed

Operations Manager

We both worked at Engro Fertilizers Limited, Pakistan during 2007 - 2008, as peers on multiple projects.

June 1, 2016 on LinkedIn

" I had an opportunity to work with Tauseef in Engro Fertilizers Ltd as a peer. He was amongst the most competent Process design engineers having excellent simulations skills and strong conceptual approach. Moreover Tauseef was good team player with easy going and supportive approach for rest of the group members. "

Usman Muhammad Sharif

Head of Non-Fuel Retail Business | Petromin Corporation KSA

Ex Coordinator - Dramatic Society - UET Lahore

We both studied at UET Lahore during 2001 - 2005, as class fellows

September 18, 2016 on Internal Group

"[Written in English scriptted Urdu language] Translate in English

One word: Keem-ya-gar, Baba gee

Hum mey koi genius hai to Tu hai. Kisi aur zamaney mey Tu Stefan Hawkings key saath Black hole theory per kaam ker raha hota ya phir Pakistan key liyey first rocket,satellite launch per kaam ker raha hota.

Mujhey aaj bhee mechanical waaley Ali Zaidi ka tujhey challenge Yaad hai. My. Pata nahi kahaan sey aya hai tu. Kis ney sikhaaya hai Tujhey yeh sab kuch.

Ooper sey khaaksaari ka yeh alam hai key na poocho. Balkey please poocho. Man chaley ka sauda mey mochi firdous Jamal shayed terey pey likha gaya thaa.

Dramatics mey agar kisi ney hamari productions mey jaan daali to wo Tu hi thaa. Jis tarha waseem akram ka team mey hona hi kafi thaa, waisey teri team mey presence hi kaafi thi. Tu thaa to raastey nikal ayey. My pehli dafa tu alhamra mey bethaa aur lights waaley ki po phar dee. Saalon sey theatre kerney waaley Peerzaadaas stage per kehney lagey, every one should learn from this guy.

Pata nahi tu kahan ghayeb hai. Ho sakta hai key tu Khudayi taakton sey mil ker kisi super secret mission per Dunya ko save kerta ho ya phir hum jaisey kisi bhatkey huyey ki Keemyagiri kerta ho. Shayed tu hamari bhee koi madad kerney bheja gaya thaa. "

Bilal Hameed

Interconnection & Process Expert | Sr. Manager Interconnect Management

TechniColor Team - Dramatic Society - UET Lahore

We both worked together at Dramatic Society, while studying at UET Lahore during 2001 - 2005.

October 9, 2005 on UET Dramatic Society MSN Group

" My Best Friend, My Partner, My Boss, My brother, My Doost, My Fav Person in Whole UETDS....... That person dont belong to Humans .... he is JIN .... simply Genious ....a persons with Kamal concept and idea about things he has ever studied or heard about.... a true Engineer .... i am proud to be a person who has worked mostly with him ... it was second Annual Function on which we were together on control Panels ...every time in whole year i am with him ... going to hall road .... going to Shah-Almi ... going to each and every corner of lahore .... in search of completing our ideas ..... the best kharrabi in that person is that he always completes his work on dead line .... not before that ...and i am very angry with him for that .... but the problem is that he always completes it in best of Way ..... Frankly speaking i am Jelous of that person ... so much perfection ..... so much idealism ... "

Follow me @

engOneer

Science Of Signs

Education

GRADUATION - UNIVERSITY DEGREE

I earned my degree in Chemical Engineering from the University of Engineering & Technology, Lahore, Pakistan, graduating in 2005 with distinction, securing an A Grade and achieving an impressive overall score of 74.34%. Throughout the four-year program, I actively engaged in several impactful study projects, each contributing to my comprehensive understanding of the field. Some notable project titles include:

- Optimization of Process Plant; supervised by Prof. Dr. A.K. Salariya

- Conceptual Design Of Combined Cycle Power Plant; supervised by Prof. Shah Muhammad

- Production Of Mixed Xylynes From C9+ Aromatics

[Supervised by Prof. Dr. Shahid Bashir.]

Scanned Copy of Bachelor Degree Certificate

Scanned Copy of Detailed Marks Certificate

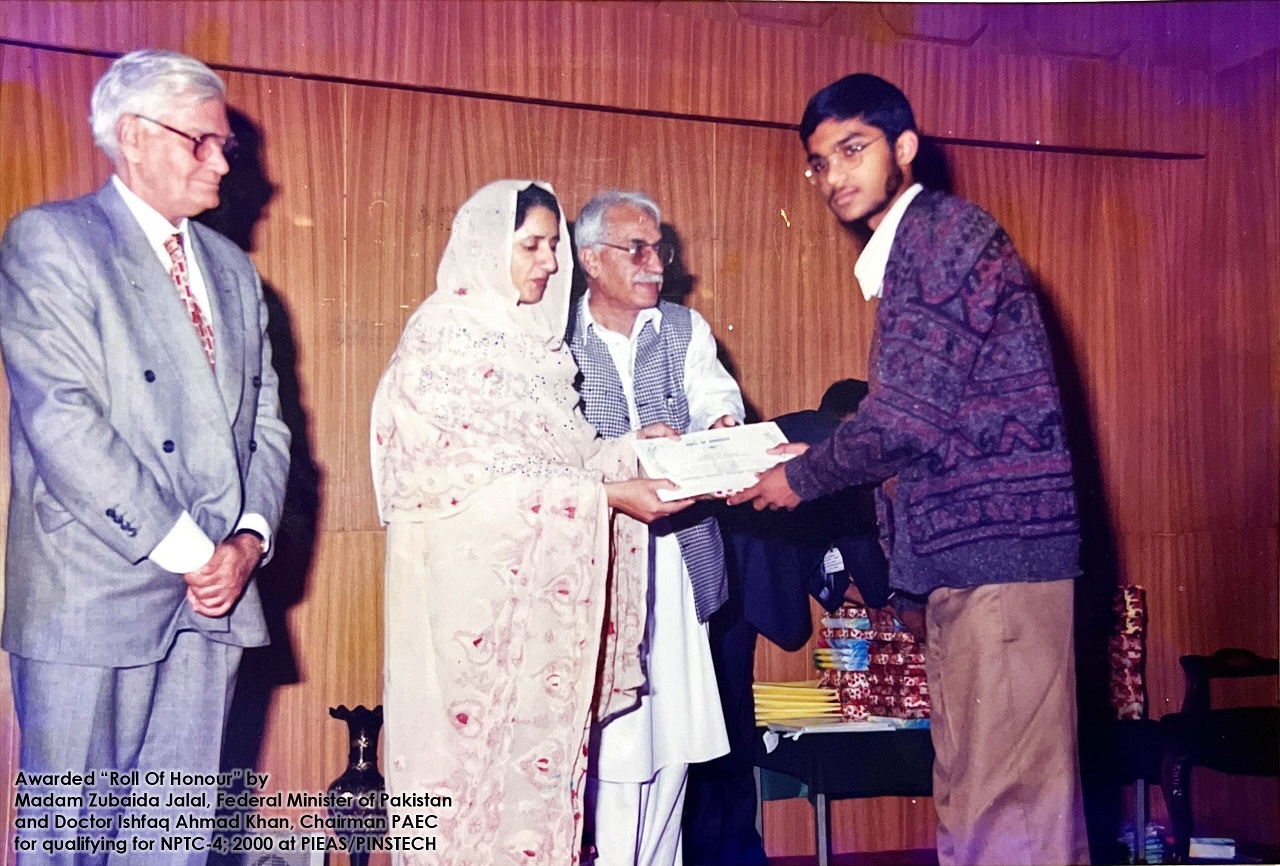

HIGHER SCHOOL DEGREE

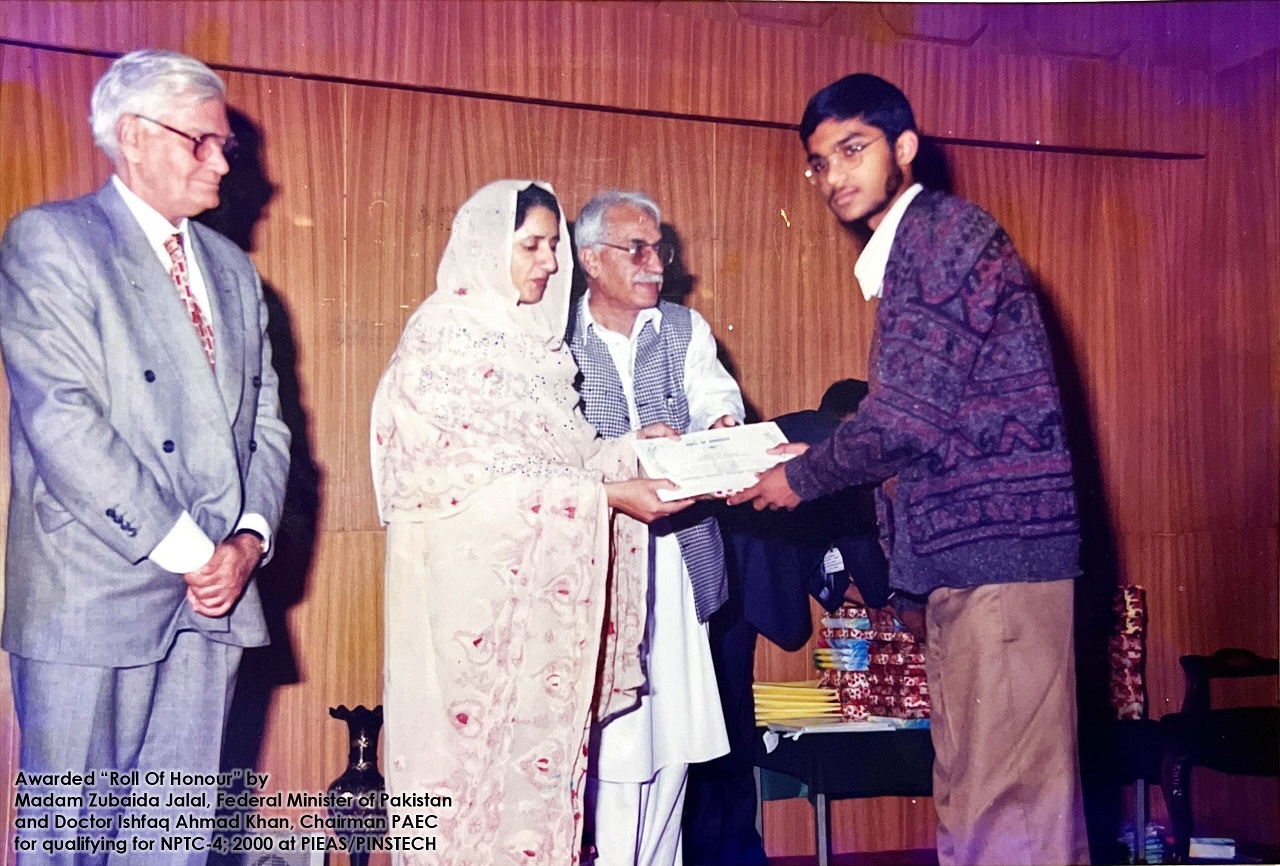

I earned my high school degree with a major in pre-engineering, achieving an aggregate score of 77.63%. During high school, I had the privilege to participate in the National Physics Talent Contest (NPTC) and was selected among the top students in Pakistan in the year 2000. This competition provided a platform for engaging in a week-long series of physics-based activities, research endeavors, and discussions facilitated by Pakistan`s esteemed physicist, Mr. Pervaiz Hoodbhoy, at the renowned facilities of Pakistan Institute of Engineering and Applied Sciences (PIEAS). This immersive experience not only broadened my understanding of physics but also allowed me to interact with and learn from one of the country`s most distinguished physicists.

Roll Of Honour - NPTC

I earned my degree in Chemical Engineering from the University of Engineering & Technology, Lahore, Pakistan, graduating in 2005 with distinction, securing an A Grade and achieving an impressive overall score of 74.34%. Throughout the four-year program, I actively engaged in several impactful study projects, each contributing to my comprehensive understanding of the field. Some notable project titles include:

- Optimization of Process Plant; supervised by Prof. Dr. A.K. Salariya

- Conceptual Design Of Combined Cycle Power Plant; supervised by Prof. Shah Muhammad

- Production Of Mixed Xylynes From C9+ Aromatics

This project was started because of a special process described in an ExxonMobil patent. We wanted to understand how the ExxonMobil TransPlus process works, including how it`s introduced, the steps involved, how we choose things, and how we design important equipment like the Fractionator, Heat Exchangers, Fired Heater, Gas-Solid Catalytic Reactor, and Liquid-Gas Separation Units.

The process is complicated because it has more than 20 parts. We had to be very careful with how we balanced materials and energy to design it properly. To help with this, we used computer tools like MATLAB, as well as MS Excel and VBA.

My job involved designing heat exchangers, figuring out mixtures using special numbers, using this in the design of the distillation column (Fractionator), two-phase separators, and simulating heat exchangers. I did all the calculations myself using Excel-VBA to make things easier and try different ideas. I also helped with making sure the plant balanced heat and mass properly, came up with ways to control the process, estimated costs, and made sure we followed environmental rules.

This project was mainly about learning more about chemical engineering. The report and software we made might have some mistakes because this was our first time trying something like this. Here are some of the calculations we came up with for this project.

- Flash Calculator

- Bubble Point & Dew Point Calculator

- Shell & Tube Heat Exchanger Calculator

- Fractionator [Distillation Column] Calculator

[Final Year Project]The process is complicated because it has more than 20 parts. We had to be very careful with how we balanced materials and energy to design it properly. To help with this, we used computer tools like MATLAB, as well as MS Excel and VBA.

My job involved designing heat exchangers, figuring out mixtures using special numbers, using this in the design of the distillation column (Fractionator), two-phase separators, and simulating heat exchangers. I did all the calculations myself using Excel-VBA to make things easier and try different ideas. I also helped with making sure the plant balanced heat and mass properly, came up with ways to control the process, estimated costs, and made sure we followed environmental rules.

This project was mainly about learning more about chemical engineering. The report and software we made might have some mistakes because this was our first time trying something like this. Here are some of the calculations we came up with for this project.

- Flash Calculator

- Bubble Point & Dew Point Calculator

- Shell & Tube Heat Exchanger Calculator

- Fractionator [Distillation Column] Calculator

[Supervised by Prof. Dr. Shahid Bashir.]

Scanned Copy of Bachelor Degree Certificate

Scanned Copy of Detailed Marks Certificate

HIGHER SCHOOL DEGREE

I earned my high school degree with a major in pre-engineering, achieving an aggregate score of 77.63%. During high school, I had the privilege to participate in the National Physics Talent Contest (NPTC) and was selected among the top students in Pakistan in the year 2000. This competition provided a platform for engaging in a week-long series of physics-based activities, research endeavors, and discussions facilitated by Pakistan`s esteemed physicist, Mr. Pervaiz Hoodbhoy, at the renowned facilities of Pakistan Institute of Engineering and Applied Sciences (PIEAS). This immersive experience not only broadened my understanding of physics but also allowed me to interact with and learn from one of the country`s most distinguished physicists.

Roll Of Honour - NPTC

Experience

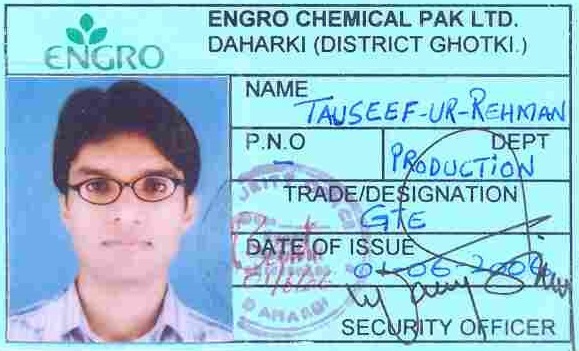

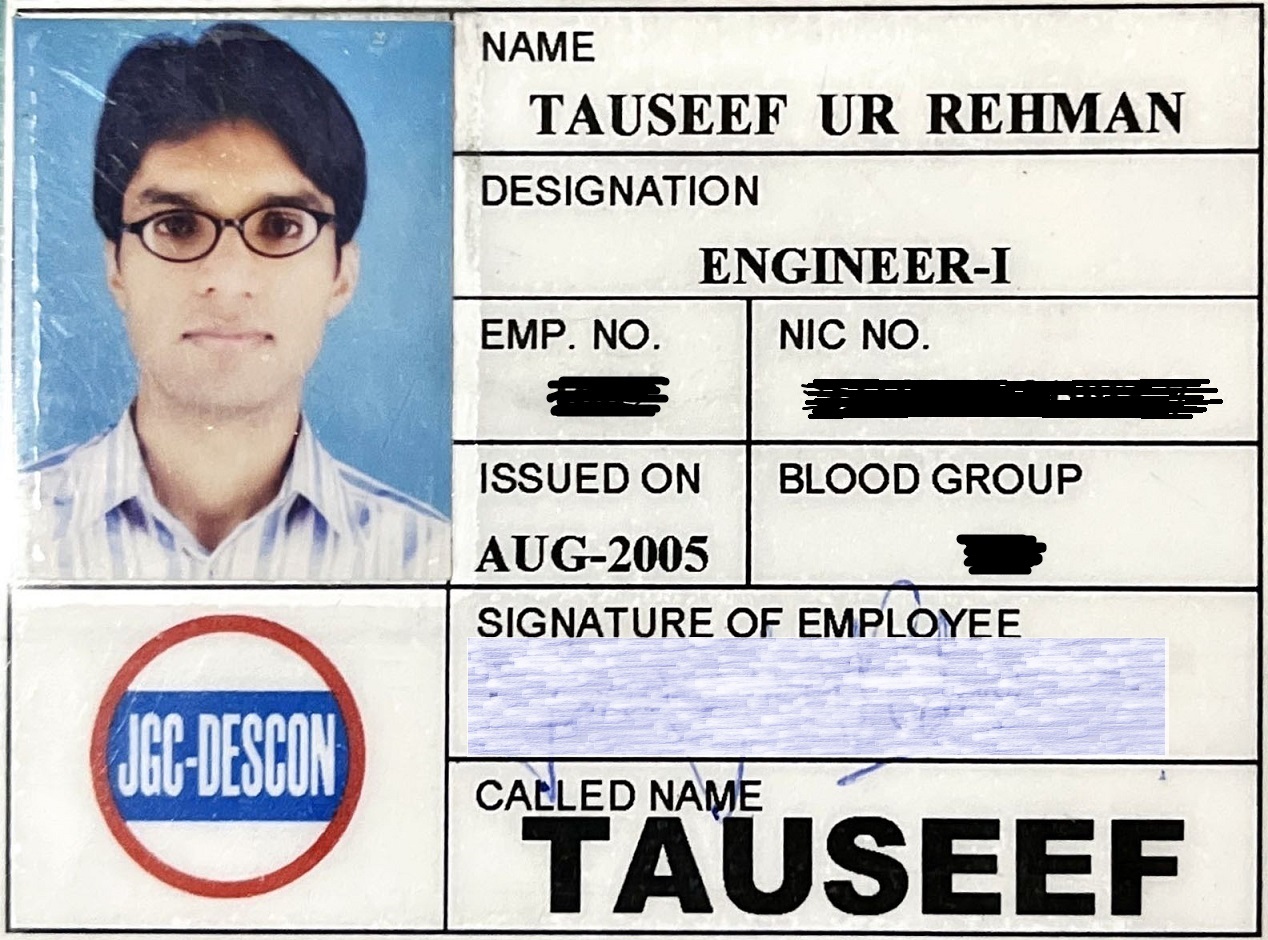

Driven by a passion for design, I embarked on my professional journey at JGC-Descon, a distinguished engineering company, where I honed my skills in conceptualizing and enhancing design methodologies. This initial step laid the foundation for my trajectory, and today, I stand as a seasoned engineering professional with a robust 17-year track record specializing in Process Design and Engineering. My extensive experience spans diverse sectors, including Fertilizers, Petrochemicals, and Gas plants, where I have garnered expertise in the intricate realms of Hydrogen, Ammonia, Amines, and Utilities. Key competencies that define my professional prowess include:

- Process Design Engineering

- Steam Reforming (SMR, ATR)

- Petrochemical Processes

- Process Design Simulation

- Gray & Blue Hydrogen Concept

- HYSYS, AspenPlus, PROII, ThermoFlow

- Gas Turbines and Steam Turbines

- Process Safety, Risk Management

- Process Hazard Analysis, HAZOP, FMEA

- Cause & Effect and Function Logic Diagrams

- Process Engineering Software Development

- PFDs, P&IDs, HFDs, and H&M

- Business Development, Techno-Commercial Feasibility

- ESD and DCS Process Control Logics

- Catalyst Health Monitoring, Replacement & Reduction

- Excel & VBA

PROFESSIONAL EXPERIENCE PROFILE:

Technip Energies (T.EN), Netherlands

Senior Process Design Engineer | Jul 2024 - present

Responsible for designing, proposing, researching and creating possible solutions for an optimized Hydrogen production facility, complying to client requirements.

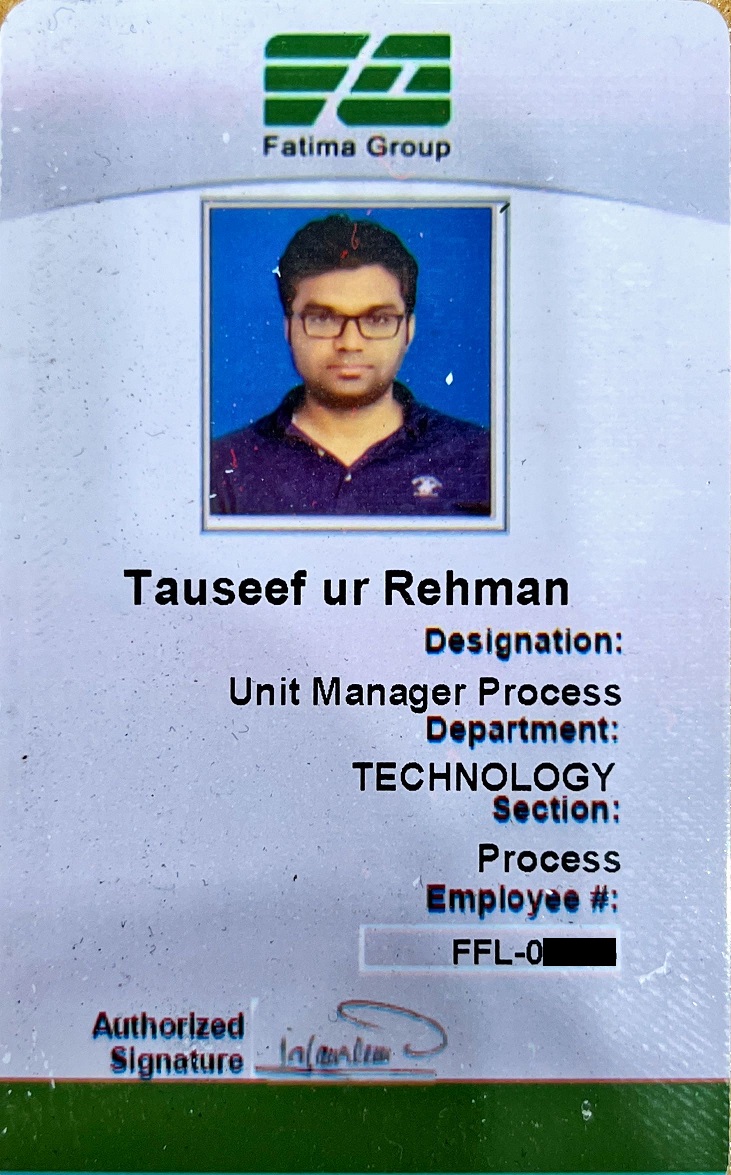

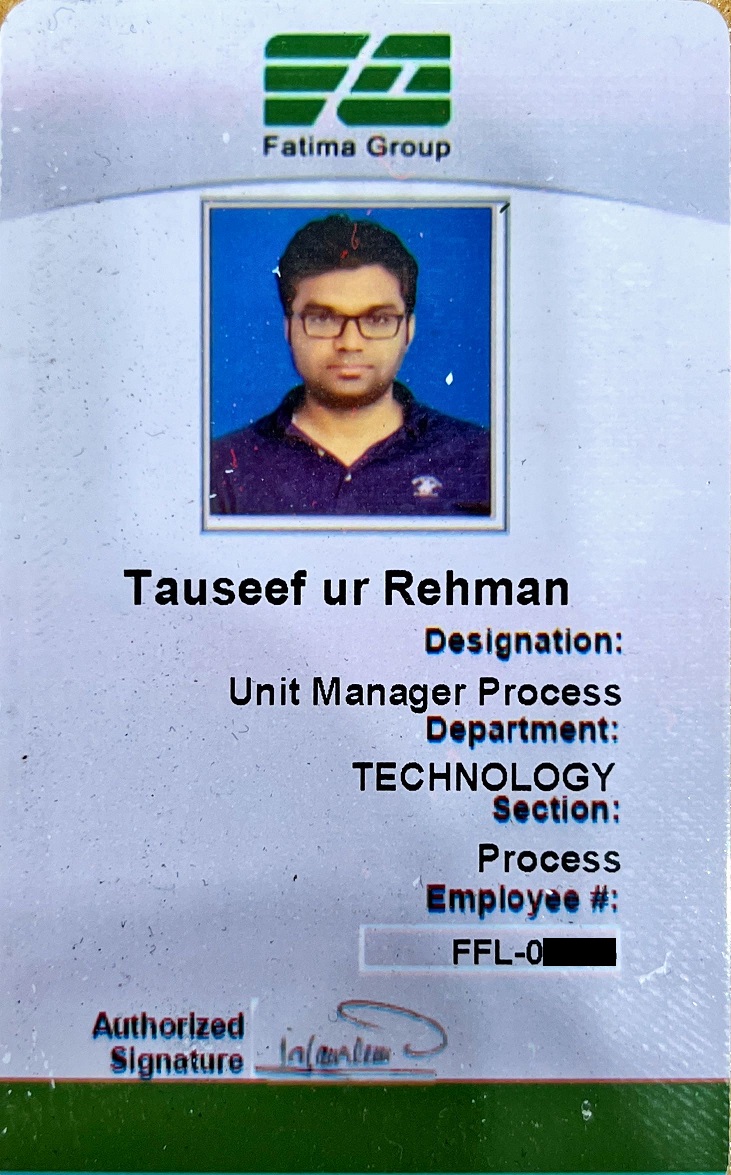

Fatima Fertilizers Limited, Pakistan

Process Engineering Unit Manager | Sep 2016 - Jun 2024

Leading a team of engineers in developing and implementing process improvement initiatives, resulting in significant cost savings and efficiency gains.

Key Achievements:

- Overseeing and spearheading Process Design and Engineering initiatives to facilitate the transition of Group Power plants from international coal to indigenous resources. Additionally, implementing essential environmental control measures to ensure sustainable and compliant operations.

- Developed and implemented energy management strategies in Ammonia production facilities based on the Energy Star program, resulting in significant reduction in energy consumption and $1.2 million annual cost savings.

- Conducted, reviewed technical monitoring programs (TMP) at Ammonia production facilities, enhancing group sustainability.

- Played a pivotal role in technical monitoring and auditing of power plants, fertilizer facilities, and sugar production sites.

- Conducted rigorous engineering design reviews for various projects, including Thar lignite refining, coal gasification for GTL /SNG /IGCC and a 660 MW raw lignite-based power plant.

- Contributed significantly to the due diligence and feasibility study of the 99MW Arkari Gol Hydro Power Project, resulting in a reduced carbon footprint.

- Designed a foundational proposal for a 100 MW Solar PV plant at Bahawalpur Solar Park, aligning with the company`s decarbonization vision.

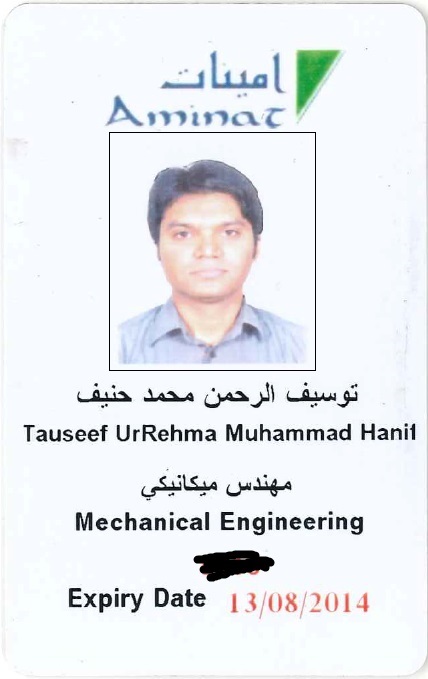

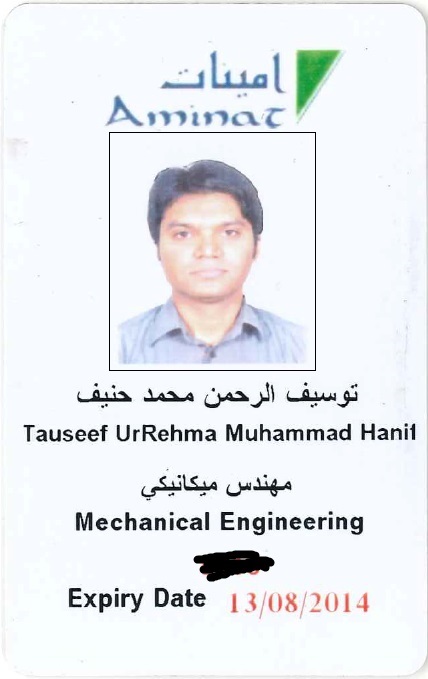

Arabian Amines Company, Al-Jubail K.S.A. Process Engineer | Jun 2012 - Aug 2016

Collaborated in multiple production and process enhancement projects aimed at boosting efficiency and sustainability within the joint venture between Huntsman Chemicals U.S.A. and Zamil Group KSA.

Key Achievements:

- Engineered strategic plant modifications, significantly enhancing efficiency and production, resulting in improved product quality and productivity.

- Pioneered the development and management of a statistics-based process simulator for a proprietary PFR (Plug Flow Reactor) using Excel.

- Held a key role as the Management of Change (MOC) coordinator for process and control documentation and implementation.

- Led and coordinated PHAs for proposed process modifications and successfully led multiple root cause analysis (RCA) efforts.

- Ensured unwavering compliance with Process Safety Management (PSM) standards and effectively implemented safety enhancement plans.

- Made substantial contributions to major projects, including Flue Gas Recirculation for utilities boiler and distillation tower internals modification.

- Conducted a thorough site-wide HAZOP revalidation in collaboration with the licensor.

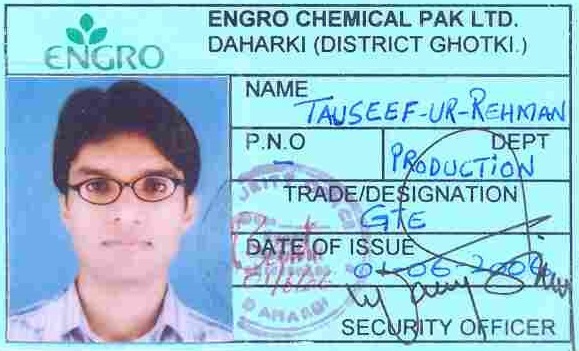

Engro Fertilizers Limited, Pakistan

Process Engineer | Jun 2006 - May 2012

Designed plant modifications to improve control schemes, enhance efficiency, and increase capacity. Additionally, responsible for monitoring plant performance and engaging in contact engineering.

Key Achievements:

- Conducted technical monitoring of Ammonia plant along with energy optimization exercises, including reactors (pre, primary & secondary reformers, low and high temperature shift convertors, methanation and ammonia synthesis reactor) profile monitoring and adjustment and plant modifications for improved production and energy indices.

- Conducted multiple optimization evaluations using HYSYS/ GIPS and custom excel worksheet, personally developed for reactor and catalyst health profiling.

- Developed a sophisticated Ammonia plant simulation model using HYSYS and Excel, ultimately optimizing process performance.

- Reviewing EP documents and actively collaborating with construction contractors during the design and construction of one of the largest single train Ammonia Complex.

- Executed a comprehensive feasibility study for a compression station, encompassing compressor package selection and seamless integration.

- Enhanced plant control and ESD systems, leading to a remarkable improvement in safety and reliability.

- Spearheaded unit conversion activities and dynamic simulations for robust control process verification.

- Executed precise catalyst change and reduction during turnarounds, resulting in optimal catalyst performance.

- Played a pivotal role in balancing the CO2 removal system and proposing optimal operating parameters.

- Contributed significantly to compressor restaging and efficiency improvement, thus enhancing site power ratings.

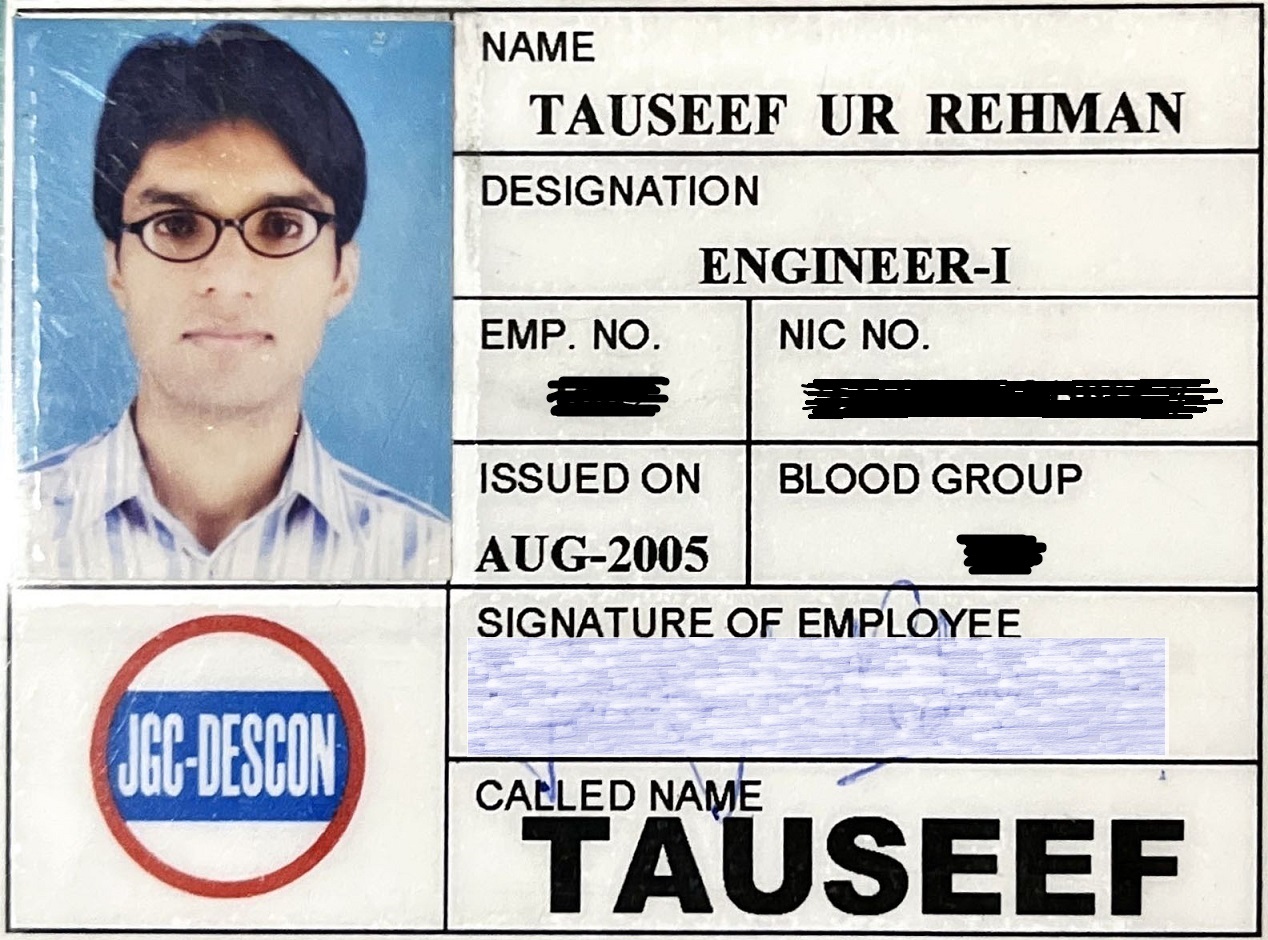

JGC-DESCON Engineering (Pvt.) Ltd. Pakistan

Process Engineer | Aug 2005 - Nov 2005, Jan 2006 - Apr 2006

In this capacity, my responsibilities encompassed both basic and detailed design engineering, involving simulation for Process Flow Diagrams (PFD), development of process control schemes, and the design and rating of heat exchangers, as well as hydraulic calculations.

Key Achievements:

- Conducted comprehensive basic engineering, including process simulation, hydraulic design of distillation columns using TRAY2000, and the design of exchangers and reboilers using HTRI.

- Led the basic design calculations for the Dehydration plant component of the Gassi Toul Project in Algeria, contributing to the Front-End Engineering Design (FEED) package.

CERTIFICATIONS:

- Advance Process Modeling Using HYSYS

- The 7 Habits of Highly Effective People

- Six-Sigma Principles

- Negotiation Skills

- Adaptive Leadership for VUCA Challenges

- Creating a Culture of Change

- Crisis Communication

- Critical Thinking for Better Judgment and Decision-Making

- Developing Adaptability as a Manager

- Executive Decision-Making

- Leading Change

- Leading Your Team Through Change

- Doing Good to Build a Profitable Business

- Risk Management

My LinkedIn Page

Download Latest Resume

.

- Process Design Engineering

- Steam Reforming (SMR, ATR)

- Petrochemical Processes

- Process Design Simulation

- Gray & Blue Hydrogen Concept

- HYSYS, AspenPlus, PROII, ThermoFlow

- Gas Turbines and Steam Turbines

- Process Safety, Risk Management

- Process Hazard Analysis, HAZOP, FMEA

- Cause & Effect and Function Logic Diagrams

- Process Engineering Software Development

- PFDs, P&IDs, HFDs, and H&M

- Business Development, Techno-Commercial Feasibility

- ESD and DCS Process Control Logics

- Catalyst Health Monitoring, Replacement & Reduction

- Excel & VBA

PROFESSIONAL EXPERIENCE PROFILE:

Technip Energies (T.EN), Netherlands

Senior Process Design Engineer | Jul 2024 - present

Responsible for designing, proposing, researching and creating possible solutions for an optimized Hydrogen production facility, complying to client requirements.

Fatima Fertilizers Limited, Pakistan

Process Engineering Unit Manager | Sep 2016 - Jun 2024

Leading a team of engineers in developing and implementing process improvement initiatives, resulting in significant cost savings and efficiency gains.

Key Achievements:

- Overseeing and spearheading Process Design and Engineering initiatives to facilitate the transition of Group Power plants from international coal to indigenous resources. Additionally, implementing essential environmental control measures to ensure sustainable and compliant operations.

- Developed and implemented energy management strategies in Ammonia production facilities based on the Energy Star program, resulting in significant reduction in energy consumption and $1.2 million annual cost savings.

- Conducted, reviewed technical monitoring programs (TMP) at Ammonia production facilities, enhancing group sustainability.

- Played a pivotal role in technical monitoring and auditing of power plants, fertilizer facilities, and sugar production sites.

- Conducted rigorous engineering design reviews for various projects, including Thar lignite refining, coal gasification for GTL /SNG /IGCC and a 660 MW raw lignite-based power plant.

- Contributed significantly to the due diligence and feasibility study of the 99MW Arkari Gol Hydro Power Project, resulting in a reduced carbon footprint.

- Designed a foundational proposal for a 100 MW Solar PV plant at Bahawalpur Solar Park, aligning with the company`s decarbonization vision.

Arabian Amines Company, Al-Jubail K.S.A. Process Engineer | Jun 2012 - Aug 2016

Collaborated in multiple production and process enhancement projects aimed at boosting efficiency and sustainability within the joint venture between Huntsman Chemicals U.S.A. and Zamil Group KSA.

Key Achievements:

- Engineered strategic plant modifications, significantly enhancing efficiency and production, resulting in improved product quality and productivity.

- Pioneered the development and management of a statistics-based process simulator for a proprietary PFR (Plug Flow Reactor) using Excel.

- Held a key role as the Management of Change (MOC) coordinator for process and control documentation and implementation.

- Led and coordinated PHAs for proposed process modifications and successfully led multiple root cause analysis (RCA) efforts.

- Ensured unwavering compliance with Process Safety Management (PSM) standards and effectively implemented safety enhancement plans.

- Made substantial contributions to major projects, including Flue Gas Recirculation for utilities boiler and distillation tower internals modification.

- Conducted a thorough site-wide HAZOP revalidation in collaboration with the licensor.

Engro Fertilizers Limited, Pakistan

Process Engineer | Jun 2006 - May 2012

Designed plant modifications to improve control schemes, enhance efficiency, and increase capacity. Additionally, responsible for monitoring plant performance and engaging in contact engineering.

Key Achievements:

- Conducted technical monitoring of Ammonia plant along with energy optimization exercises, including reactors (pre, primary & secondary reformers, low and high temperature shift convertors, methanation and ammonia synthesis reactor) profile monitoring and adjustment and plant modifications for improved production and energy indices.

- Conducted multiple optimization evaluations using HYSYS/ GIPS and custom excel worksheet, personally developed for reactor and catalyst health profiling.

- Developed a sophisticated Ammonia plant simulation model using HYSYS and Excel, ultimately optimizing process performance.

- Reviewing EP documents and actively collaborating with construction contractors during the design and construction of one of the largest single train Ammonia Complex.

- Executed a comprehensive feasibility study for a compression station, encompassing compressor package selection and seamless integration.

- Enhanced plant control and ESD systems, leading to a remarkable improvement in safety and reliability.

- Spearheaded unit conversion activities and dynamic simulations for robust control process verification.

- Executed precise catalyst change and reduction during turnarounds, resulting in optimal catalyst performance.

- Played a pivotal role in balancing the CO2 removal system and proposing optimal operating parameters.

- Contributed significantly to compressor restaging and efficiency improvement, thus enhancing site power ratings.

JGC-DESCON Engineering (Pvt.) Ltd. Pakistan

Process Engineer | Aug 2005 - Nov 2005, Jan 2006 - Apr 2006

In this capacity, my responsibilities encompassed both basic and detailed design engineering, involving simulation for Process Flow Diagrams (PFD), development of process control schemes, and the design and rating of heat exchangers, as well as hydraulic calculations.

Key Achievements:

- Conducted comprehensive basic engineering, including process simulation, hydraulic design of distillation columns using TRAY2000, and the design of exchangers and reboilers using HTRI.

- Led the basic design calculations for the Dehydration plant component of the Gassi Toul Project in Algeria, contributing to the Front-End Engineering Design (FEED) package.

CERTIFICATIONS:

- Advance Process Modeling Using HYSYS

- The 7 Habits of Highly Effective People

- Six-Sigma Principles

- Negotiation Skills

- Adaptive Leadership for VUCA Challenges

- Creating a Culture of Change

- Crisis Communication

- Critical Thinking for Better Judgment and Decision-Making

- Developing Adaptability as a Manager

- Executive Decision-Making

- Leading Change

- Leading Your Team Through Change

- Doing Good to Build a Profitable Business

- Risk Management

My LinkedIn Page

Download Latest Resume

.

Extracurricular

Embracing the more whimsical facets of my personality, let`s delve into the realm I hold dear - my extracurricular activities and hobbies.

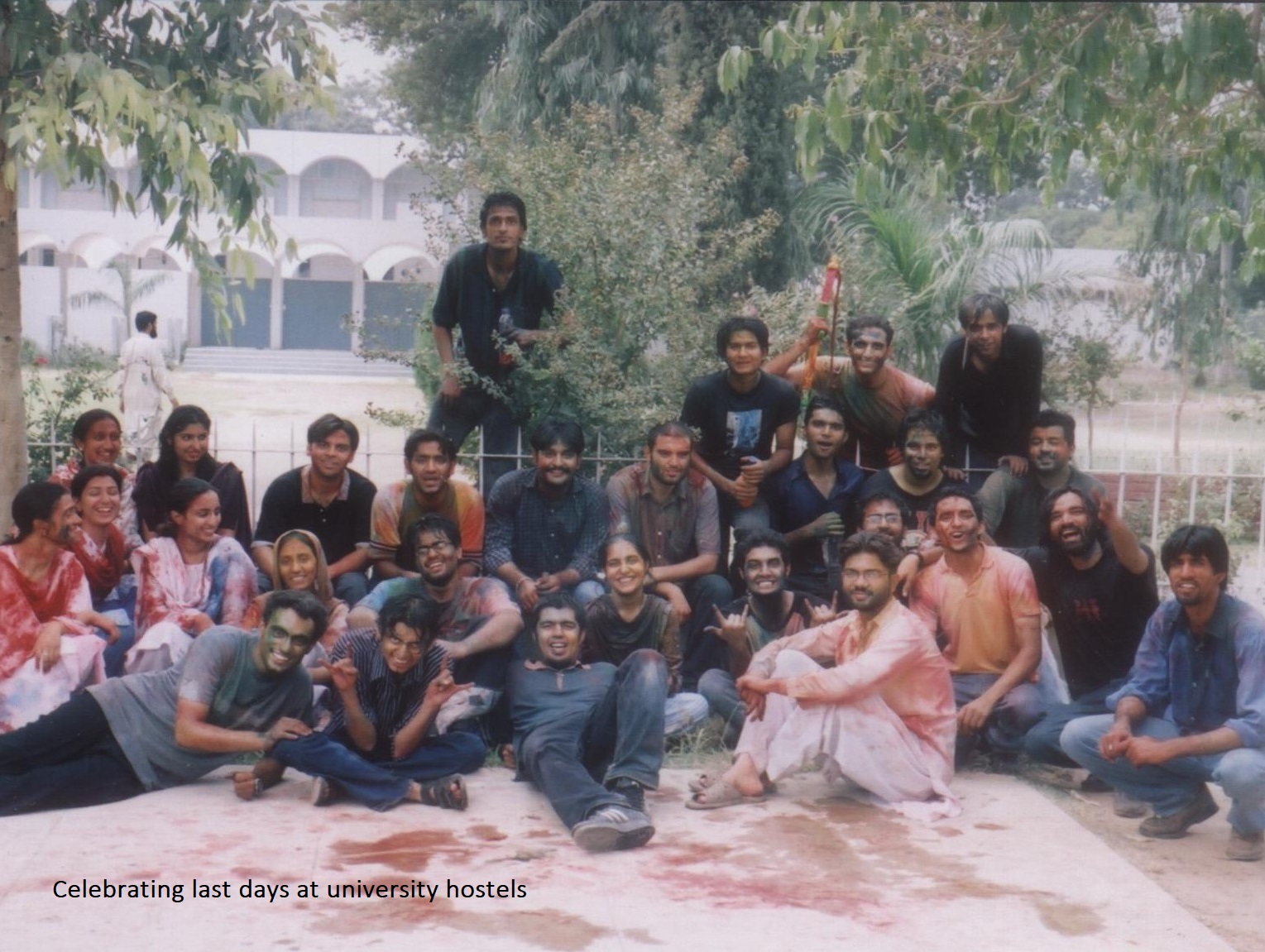

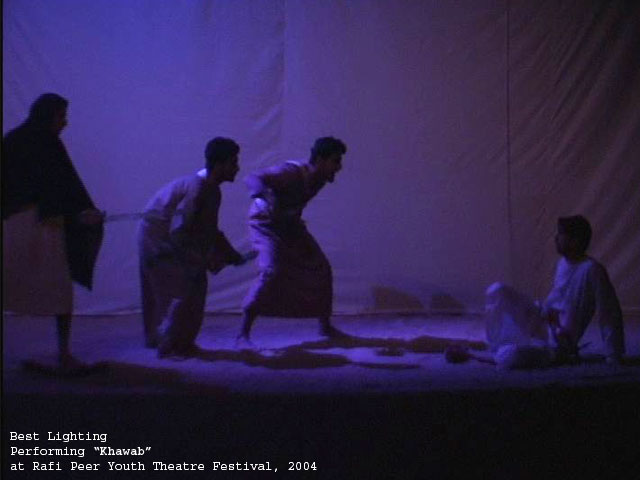

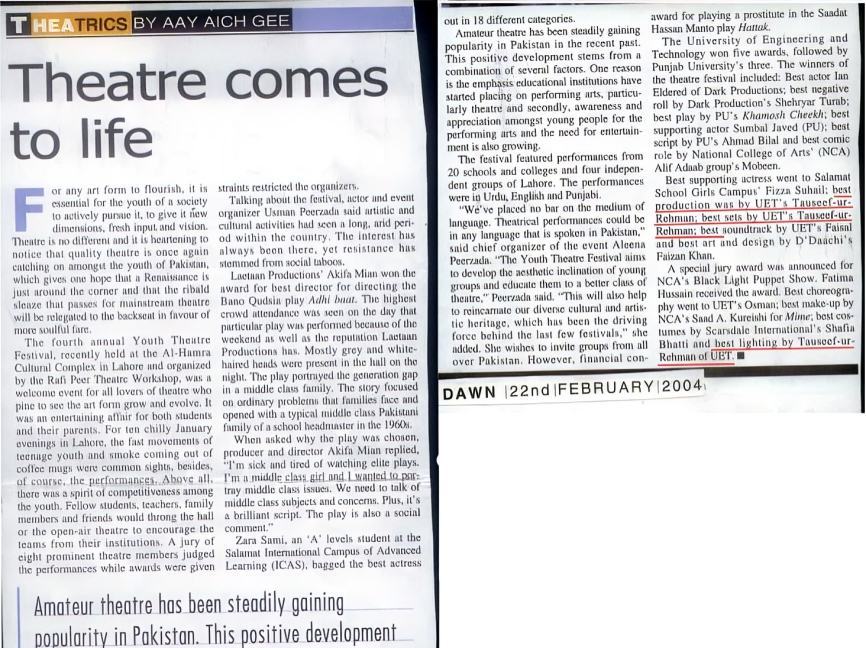

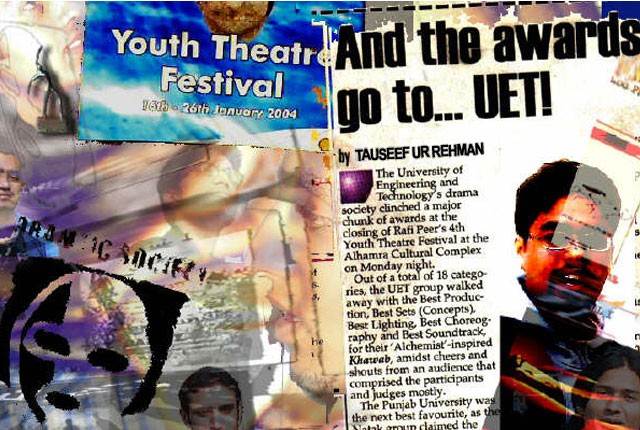

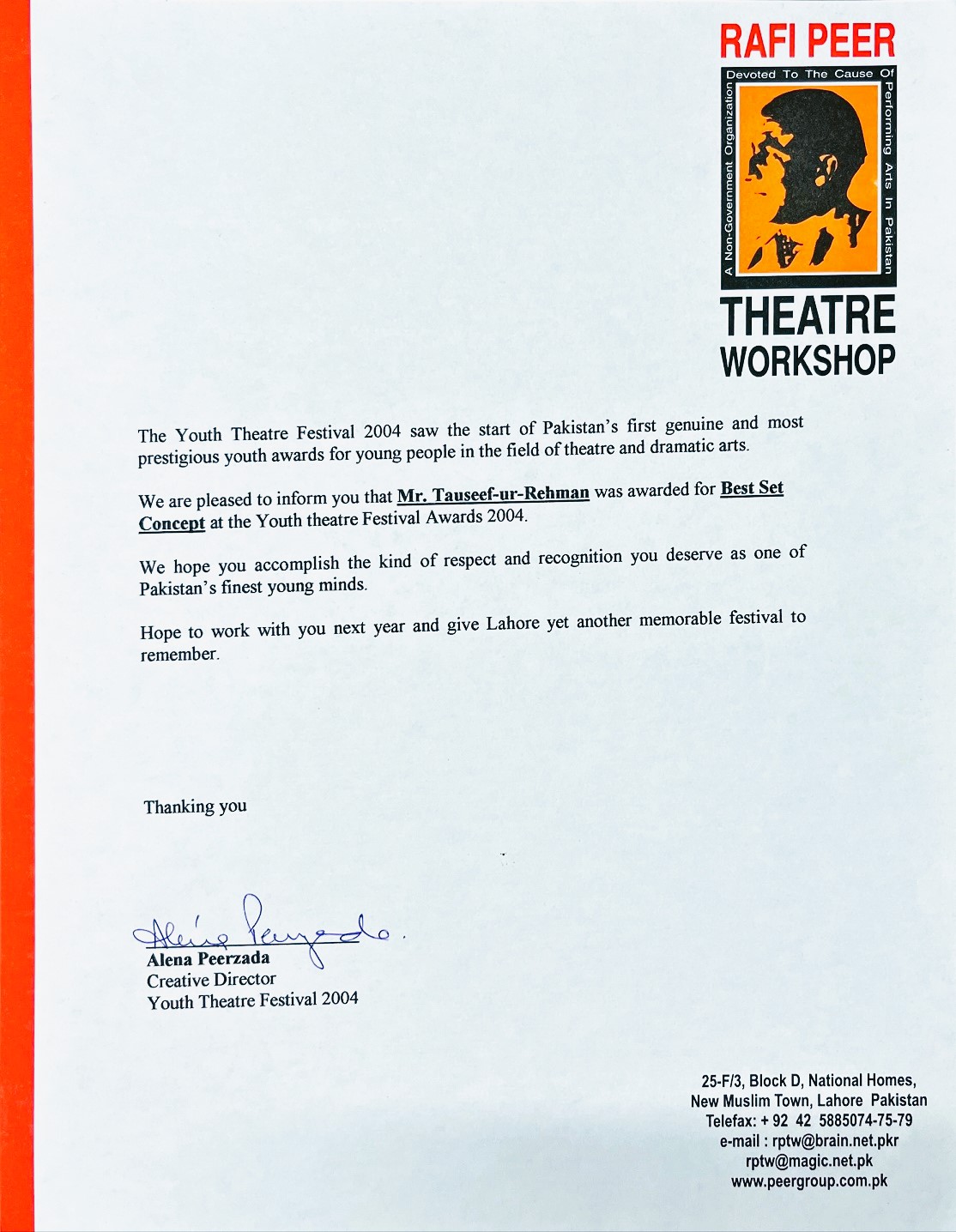

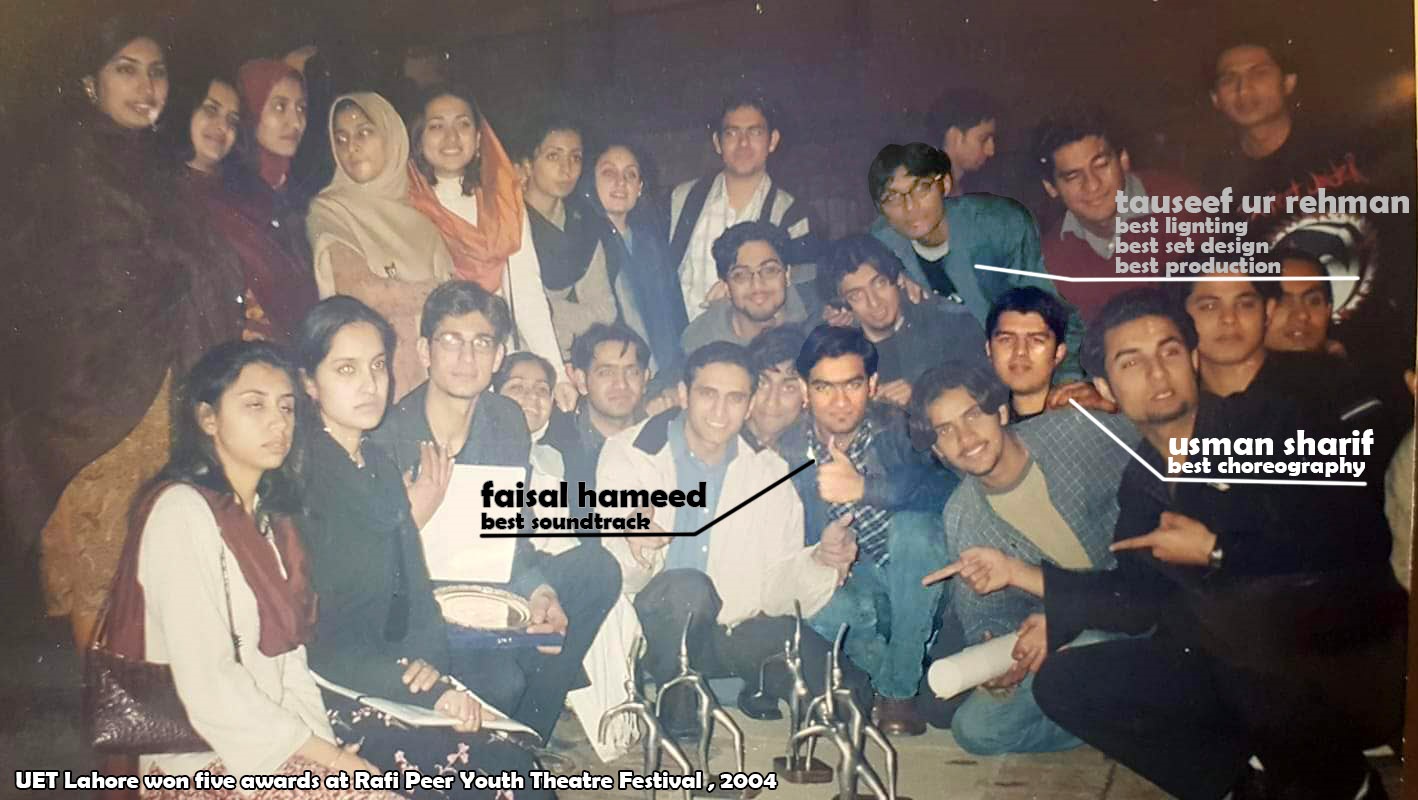

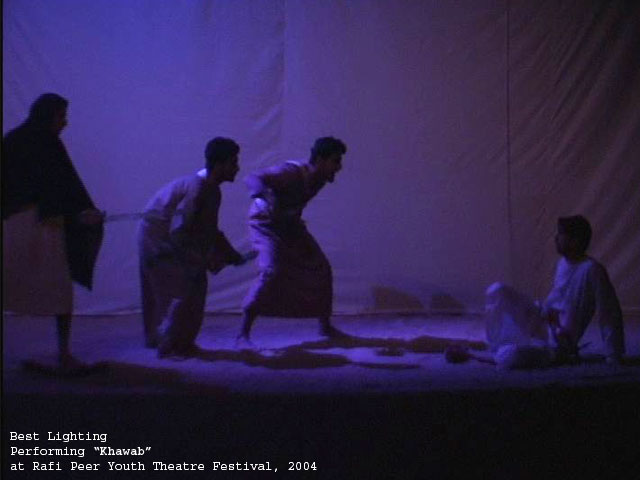

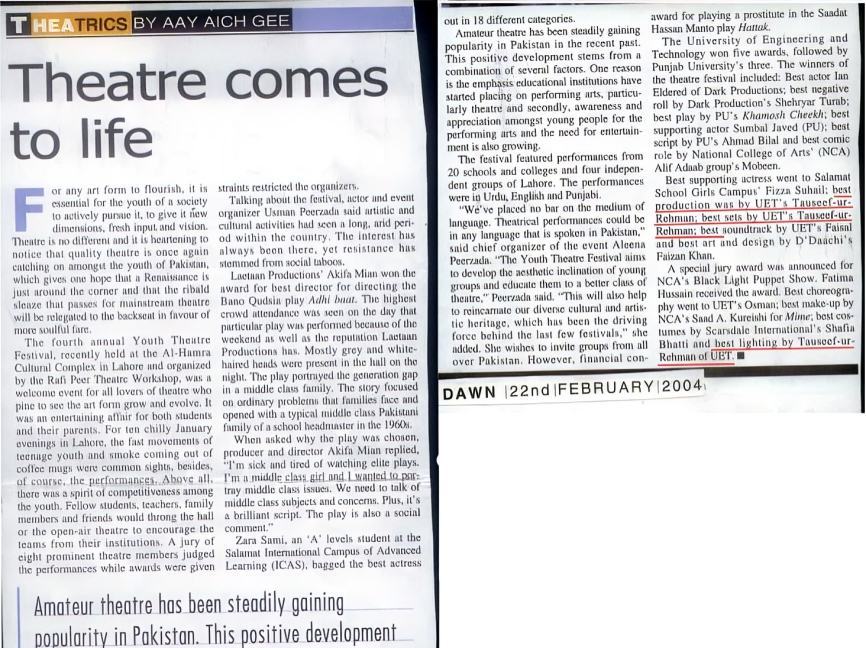

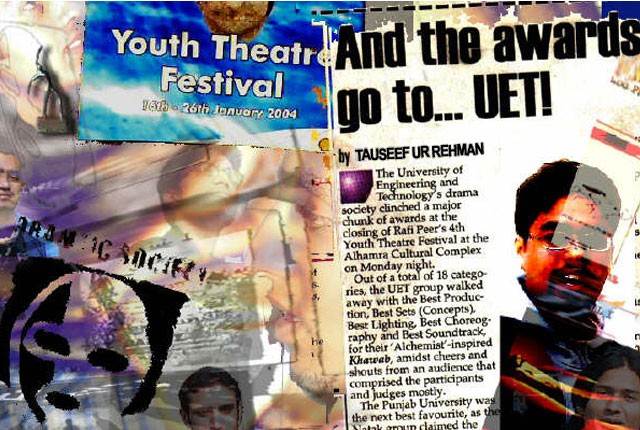

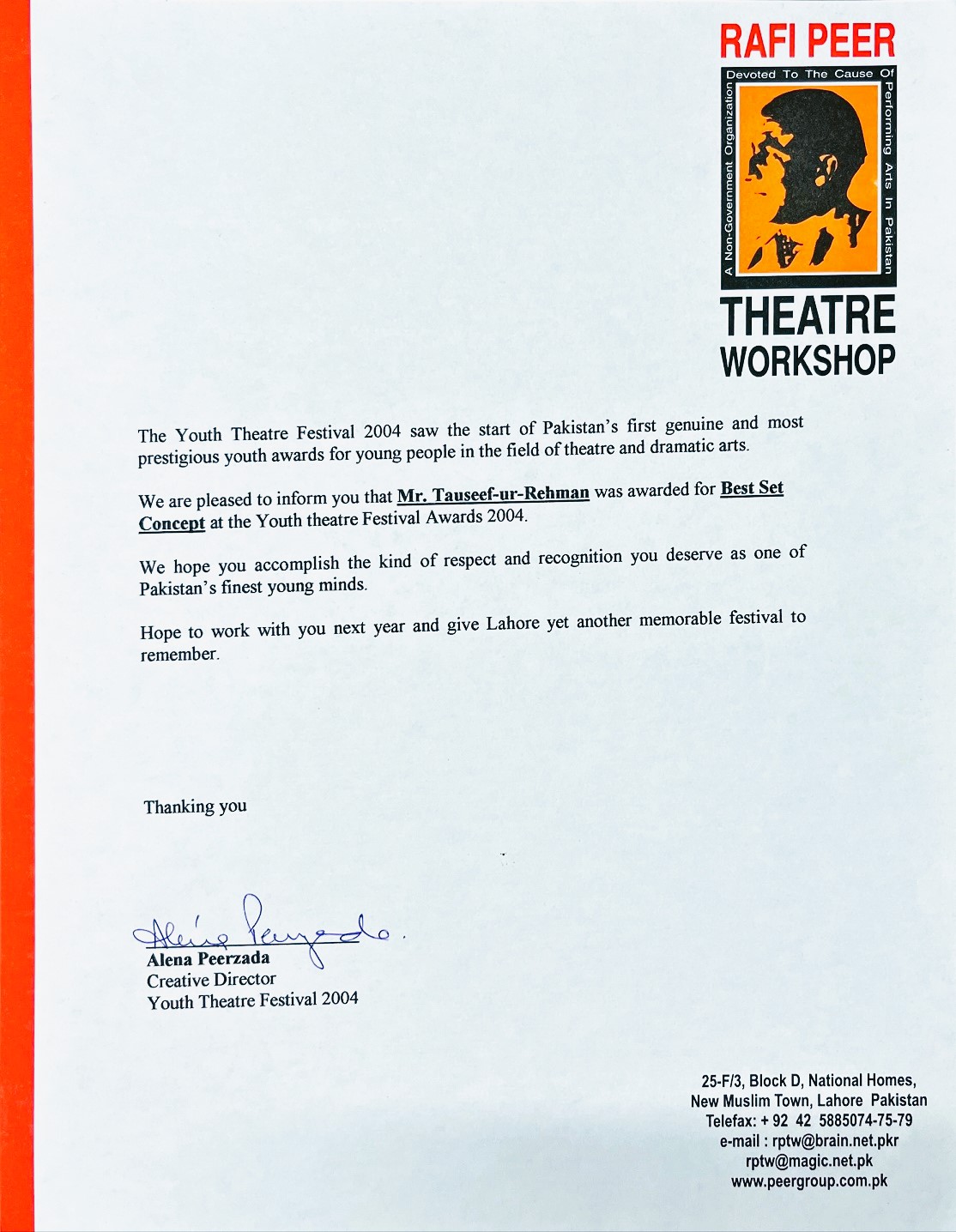

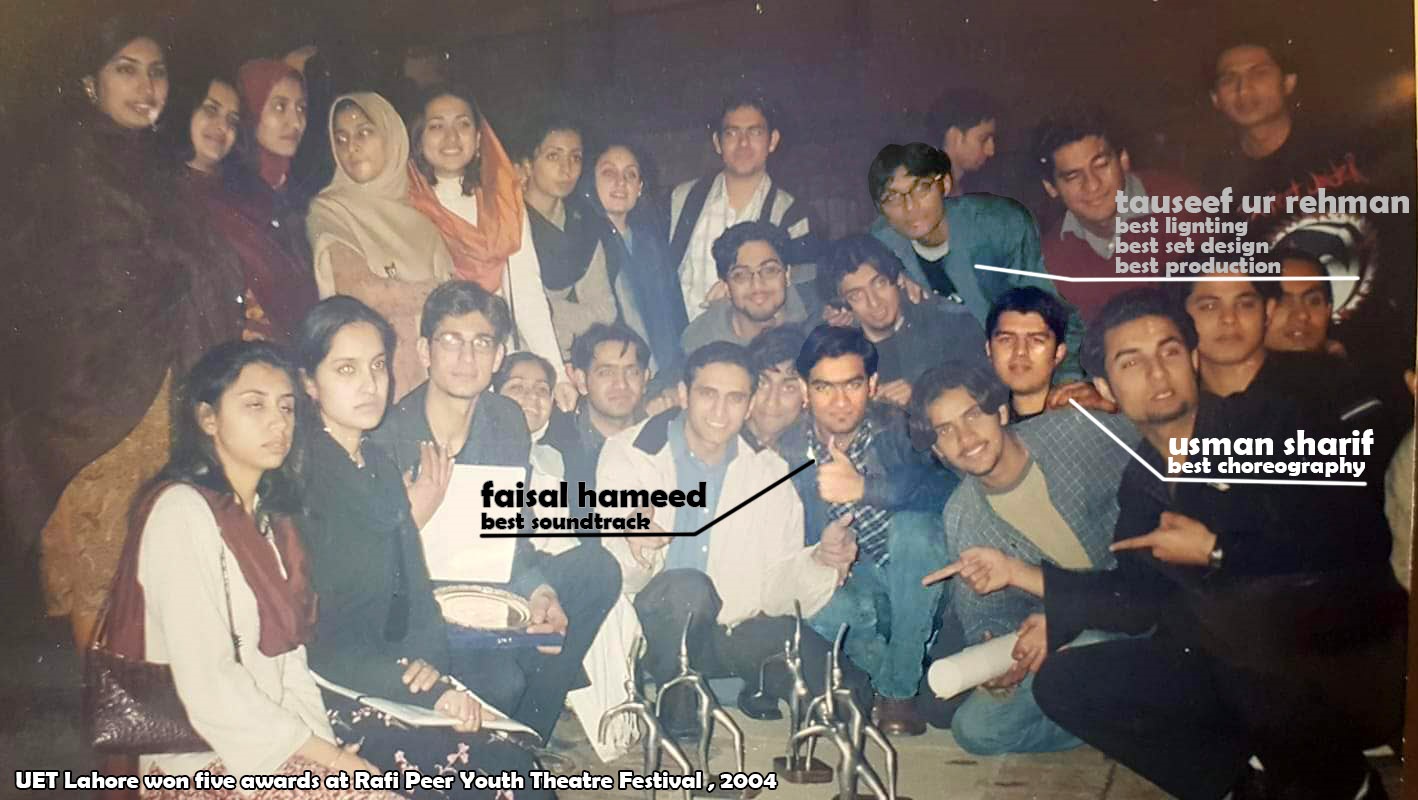

Football, a sport I adore not merely as a spectator but for the sheer joy of active participation, has been a constant companion throughout my high school days. Transitioning to university, my enthusiasm found expression in the Dramatic Society, where I contributed to elevating the artistic vibrancy of our community. The crowning achievements were three accolades at the Rafi Peer Youth Theatre Festival, clinching top honors in best lighting, best set concept, and best production categories out of 18 total, among 24 university entries.

In the digital domain, my fervor for computers unfolds as a passionate exploration of their inner workings. Along this journey, I`ve acquired proficiency in several programming languages, crafting practical tools that streamline my workflows - from Excel sheets for shell & tube exchanger simulations to software facilitating steam/gas turbine performance evaluations.

I conceptualized and built thepetrostreet.com, a professional technical discussion forum tailored for engineers, in collaboration with close friends. Actively managed from 2011 to 2018, the platform unfortunately had to be discontinued due to resource constraints. Additionally, I created specialized software tools, such as TurboMart (for efficiency calculations of steam and gas turbines), KOD Mart (Knockout Drum basic sizing and evaluation), PsychroShop (Air properties calculator) and Steam Properties Excel Addin, among others.

Collaborating with like-minded friends, I co-founded a startup called Engineering Pulse, leading the design and development of its website and creating a commercial software, named WeldPulse, sadly wrapped up after a few years.

I am currently immersed in the design and development of engOneer, an innovative online portal featuring specialized calculation modules. This platform aims to streamline engineering calculations, providing efficient tools for tasks such as turbine performance evaluations, as well as detailed profiling of typical Steam Methane reforming and shift reactions. Stay tuned for a seamless and comprehensive solution to your engineering analysis needs!

As a perpetual student of nature and science, my leisure moments are dedicated to unraveling the mysteries that captivate me. To bolster my inquisitive pursuits, I`ve constructed ScienceOfSigns.com, a web portal that, in tandem with platforms like quran.com, nasa.gov, esa.int and other science based information satiates my hunger for knowledge and exploration of nature`s wonders.

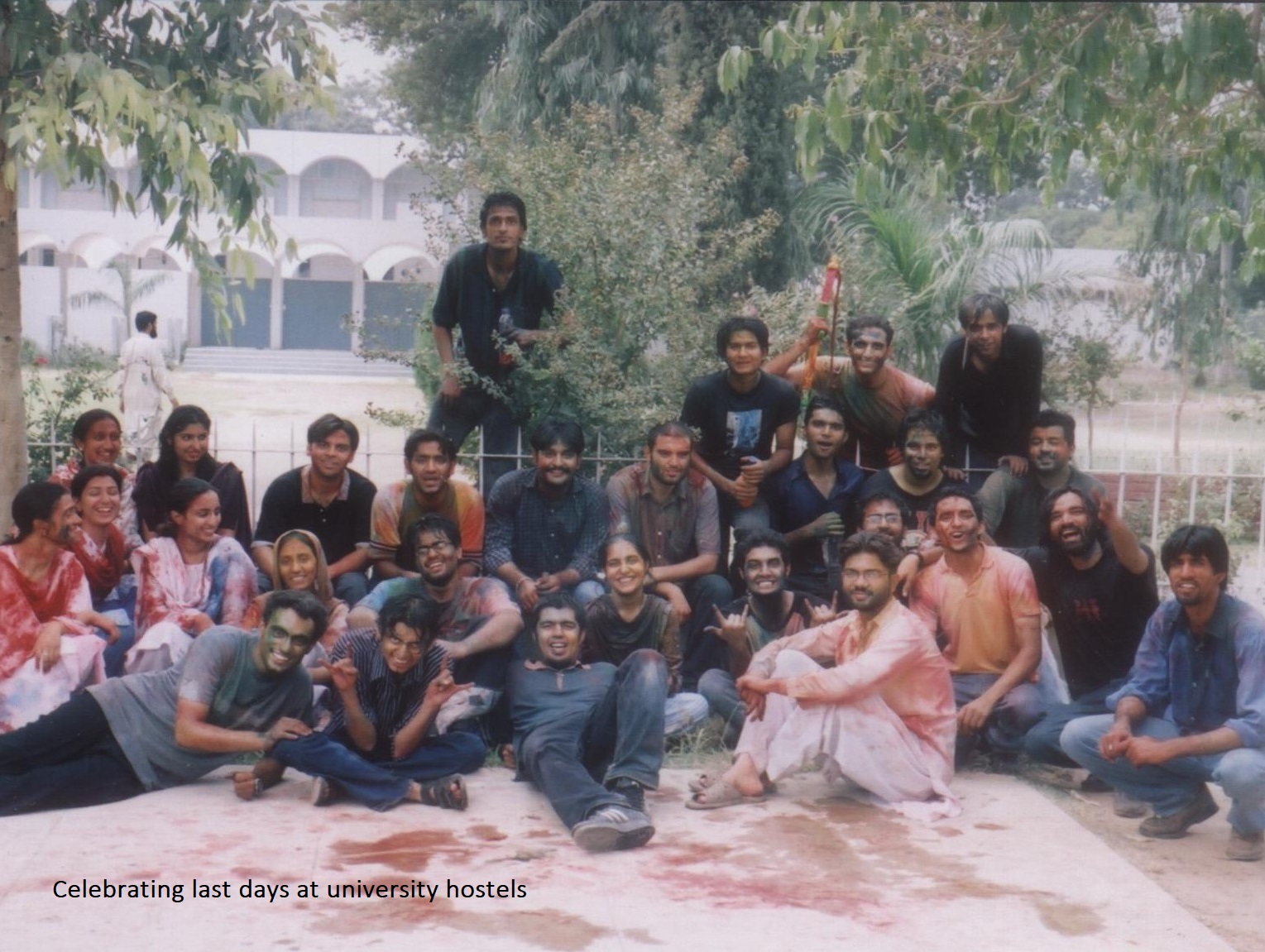

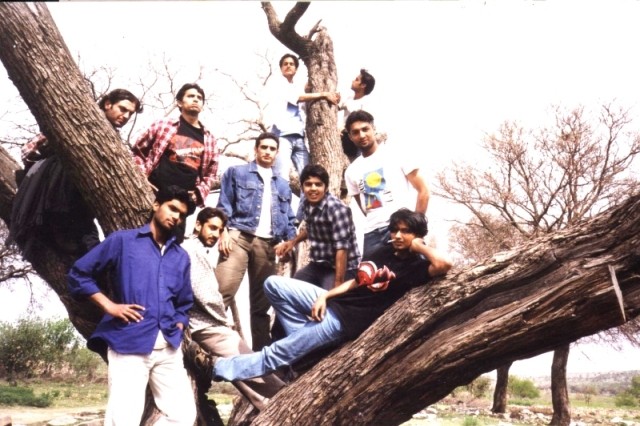

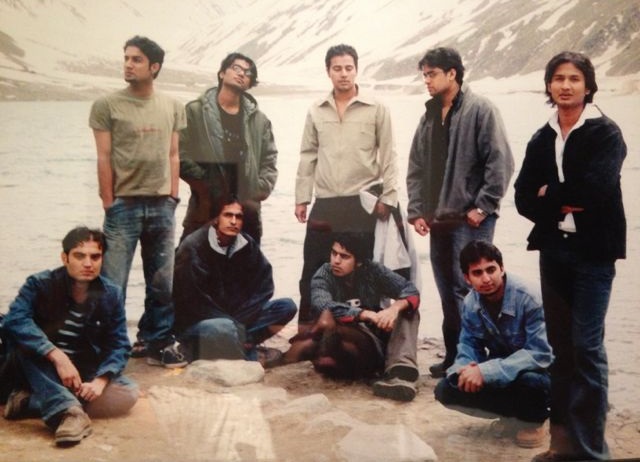

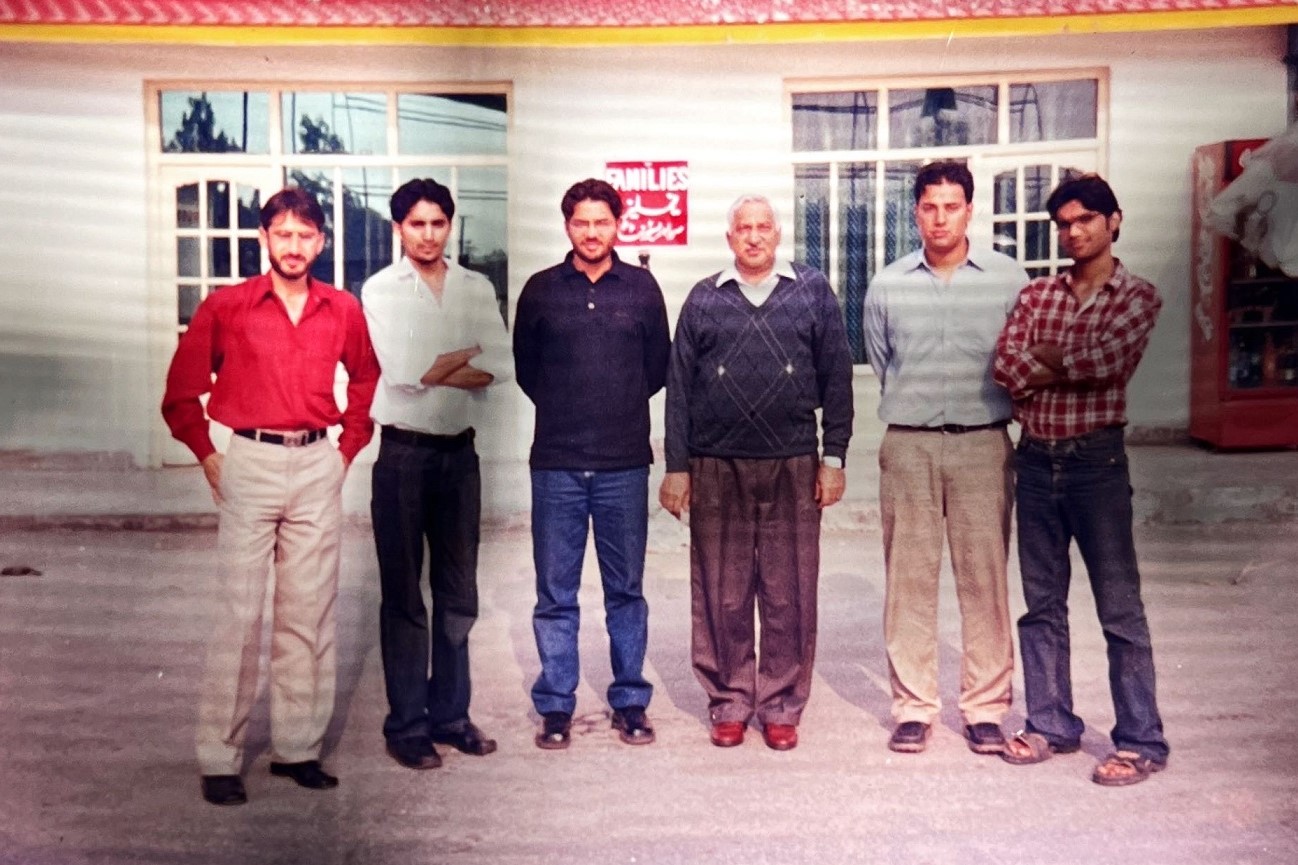

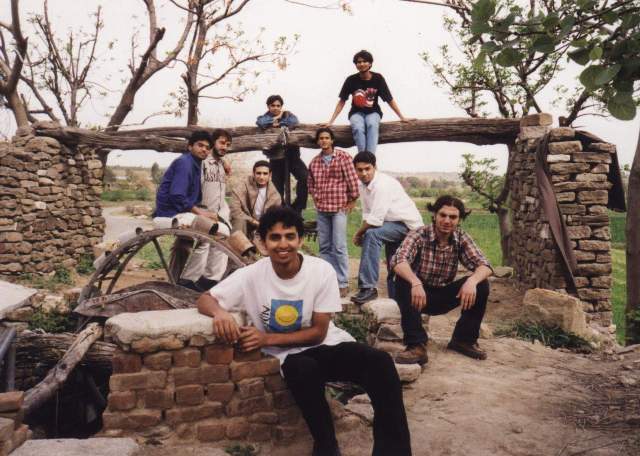

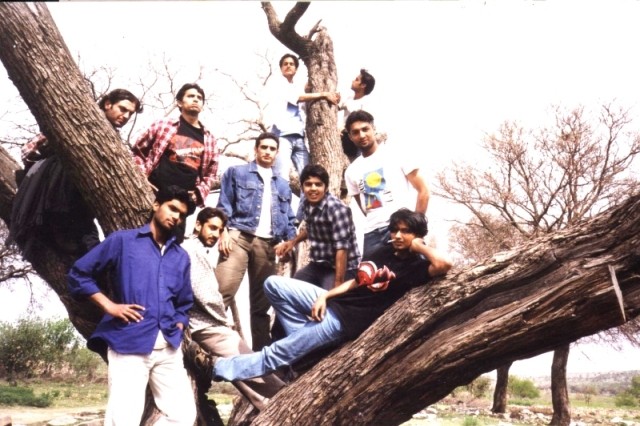

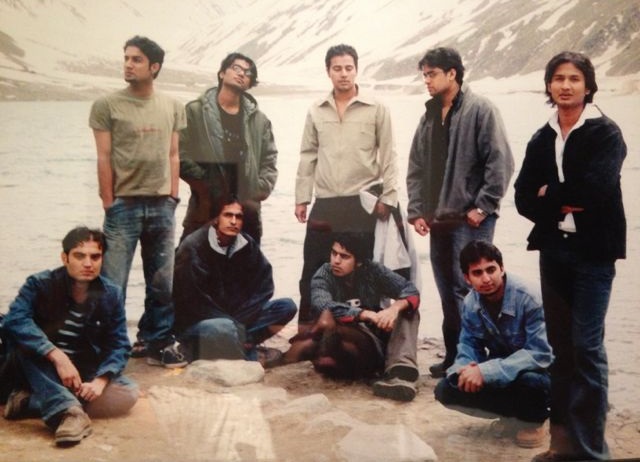

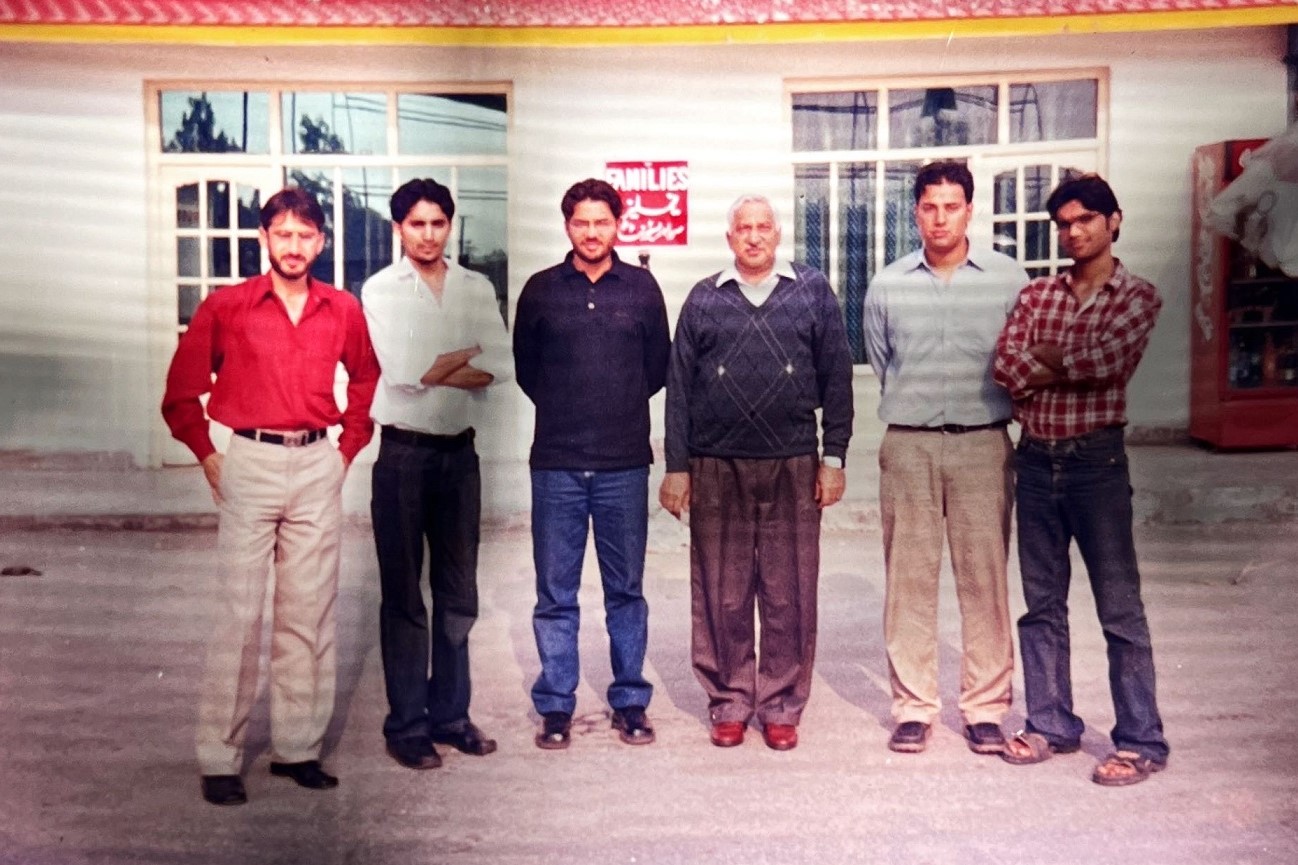

Timeless memories shared with friends

.

.

Football, a sport I adore not merely as a spectator but for the sheer joy of active participation, has been a constant companion throughout my high school days. Transitioning to university, my enthusiasm found expression in the Dramatic Society, where I contributed to elevating the artistic vibrancy of our community. The crowning achievements were three accolades at the Rafi Peer Youth Theatre Festival, clinching top honors in best lighting, best set concept, and best production categories out of 18 total, among 24 university entries.

In the digital domain, my fervor for computers unfolds as a passionate exploration of their inner workings. Along this journey, I`ve acquired proficiency in several programming languages, crafting practical tools that streamline my workflows - from Excel sheets for shell & tube exchanger simulations to software facilitating steam/gas turbine performance evaluations.

I conceptualized and built thepetrostreet.com, a professional technical discussion forum tailored for engineers, in collaboration with close friends. Actively managed from 2011 to 2018, the platform unfortunately had to be discontinued due to resource constraints. Additionally, I created specialized software tools, such as TurboMart (for efficiency calculations of steam and gas turbines), KOD Mart (Knockout Drum basic sizing and evaluation), PsychroShop (Air properties calculator) and Steam Properties Excel Addin, among others.

Collaborating with like-minded friends, I co-founded a startup called Engineering Pulse, leading the design and development of its website and creating a commercial software, named WeldPulse, sadly wrapped up after a few years.

I am currently immersed in the design and development of engOneer, an innovative online portal featuring specialized calculation modules. This platform aims to streamline engineering calculations, providing efficient tools for tasks such as turbine performance evaluations, as well as detailed profiling of typical Steam Methane reforming and shift reactions. Stay tuned for a seamless and comprehensive solution to your engineering analysis needs!

As a perpetual student of nature and science, my leisure moments are dedicated to unraveling the mysteries that captivate me. To bolster my inquisitive pursuits, I`ve constructed ScienceOfSigns.com, a web portal that, in tandem with platforms like quran.com, nasa.gov, esa.int and other science based information satiates my hunger for knowledge and exploration of nature`s wonders.

Timeless memories shared with friends

.

.

Contact

Contact Me

Thank you for reaching out! I`m thrilled to hear from you. Whether you have a question, want to discuss a potential collaboration, or just want to say hello, feel free to get in touch using the information below.

You can also follow me @

engOneer

Science Of Signs

LinkedIn

Thank you for reaching out! I`m thrilled to hear from you. Whether you have a question, want to discuss a potential collaboration, or just want to say hello, feel free to get in touch using the information below.

You can also follow me @

engOneer

Science Of Signs